Accordion Making

The traditional method of making accordions is complicated. The instrument basically consists of two wooden casings, two keyboards (one for the right hand and one for the left), a bellows and some reeds. But an accordion also requires about a hundred smaller parts, including springs, valves and decorations.

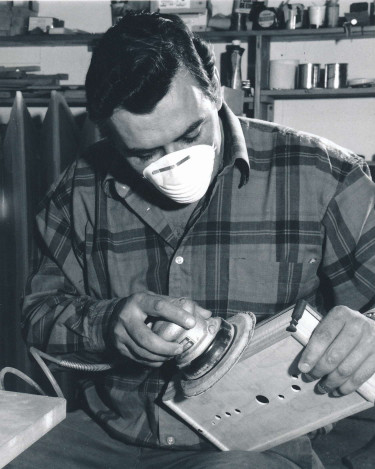

Many accordion components are made in the workshop. For example, the casings are assembled from hardwood like oak, maple or even exotic wood. Other parts, like the cardboard for the bellows and the reeds, are imported from Italy or Germany.

Before the arrival of modern tools like electronic tuning forks, accordion makers relied solely on their hearing to adjust the sound. They used small files to tune each individual reed. Even today, accordion makers complete the tuning process by hand. It takes countless adjustments to produce an instrument that is ready to play.