14

Tobacco Horn worm:The green caterpillar(larva) with five pairs of prolegs, a red horn and seven diagonal white stripes is 8.50 centimetres ( 3.5 inches) in length which develops into the Sphinx moth. The larva's colouration blends in with the tobacco leaves as it feeds leaving behind black droppings. It will burrow into the soil to pupate producing two generations a year.

16

Priming:Two or three ripe leaves are removed at one time starting from the bottom of the plant with each round of harvesting. The person, known as the primer, places the leaves under his free arm as he proceeds down the row of tobacco while bending over. Priming in this method is physically straining on the back. The tobacco is wet with dew in the morning and by noon the temperature in the fields has risen to seasonally hot.

18

Tobacco boat:A sled made of wood with steel frame and runners is pulled by horse through a row of tobacco used by the primers to place armful of primed tobacco leaves. A full boat of tobacco is taken at the end of the row to the kiln and an empty boat is hitched to the horse to be filled again.

20

Kiln:The tobacco is hung in a kiln for curing. It is a structure with a cement foundation and measures 6.60 metres by 7.31 metres (twenty-two feet by twenty four feet) and 4.88metres (sixteen feet) in height. The exterior is covered with asphalt paper and vented shingled roof. Large side doors for filling and emptying, an entrance door, four inspection doors and two sliding vents which are positioned in the upper level of the kiln complete the structure.

22

Tiers:Each kiln interior contains wood tiers on which slats of tobacco are place equal distance apart for curing and drying the tobacco leaves.

24

Cureman:Men, from the Southern United States who had earlier experience in curing tobacco using this newest method, were hired with the introduction of flu-cured tobacco to Canada. New tobacco farmers, not wanting to chance the out come of the crop, hired a Cureman until he felt confident enough to master the job himself.

25

Bulk KilnsAugust 2008

Bothwell, Ontario, Canada

Credits:

Credits:Courtesy of Bothwell-Zone & District Historical Society

26

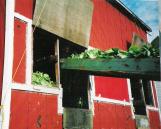

Bulk Kilns:The design of the bulk kiln is very different from the standard kiln. Lower in height with insulation to provide an air tight structure. Oil or gas fired furnace with automatic controls provides a more consistent source of heat resulting in less spoilage of the tobacco leaves.

27

Stripping TobaccoSeptember 2008

Bothwell, Ontario, Canada

Credits:

Credits:Courtesy of Bothwell-Zone & District Historical Society