14

Cutter Room8 December 1955

Powell River, British Columbia, Canada

Credits:

Credits:PC-CU1

R.F. Metcalf, photographer

Reg Halford

15

For 12 years the four machines met the demand for Powell River newsprint. Their efficiency gradually improved until 250 tons on newsprint were turned out daily and the yearly average increased to 70,000 tons.Marketing the Company's product was often difficult and uncertain. Mills in the United States were producing enough newsprint to care of their own country's demands.

Beginning in 1920, there was a huge increase in world demand for newsprint and pulp wood products. With it came a phenomenal expansion of Canada's Pulp and Paper Industry. Mills sprang up throughout the country. Canada's production of news print in 1920 was 875,000 tons; in 1929 it was approximately 1,750,000 tons.

1925 saw the beginning of the expansion for Number 5 and Number 6 paper machines. In 1926 a two-storey concrete building 541 feet long and 234 feet wide was constructed. In it were installed stock preparation equipment, two 234-inch Walmsley (221 inch trim) high-speed paper machines and roll-wrapping and labeling facilities. When the new machines were started they doubled the mill's output to 500 tons a day.

Bill Thompson

The Powell River Mill Story

17

The first of the new machines, No. 5, began making paper on June 21, 1926. The machine was powered by a Harland electric drive, complete with a separate motor-generator and an individual motor for each section. It also had a steam turbine which could drive the generator independent of the mill power supply in the event of a power shortage due to low water level in the lake. No. 5 had a fourdrinier wire 232 inches wide. It began producing paper at 500 feet per minute.The speed would be gradually increased to about 1000 feet per minute (about 11 m.p.h.)

In September 1926, No. 6 Machine, a mirror-image of No. 5, began making paper. Total mill production for October 1926 was about 11,470 tons. About 42 percent of that total was from the two new machines, which were not yet up to rated speed. By the beginning of 1928 they had raised plant daily production to 450 tons. In January 1930 the figure was 500 tons.

Bill Thompson

The Powell River Mill Story

18

Number 5 and 6 Paper MachinesCirca 1930

Powell River, British Columbia, Canada

Credits:

Credits:A27-13-1

Leonard Frank, photographer

19

In spite of greatly increased production, it was not long before the demand for Powell River newsprint again exceeded the mill's capacity and further expansion was necessary.In 1930, another building, designed to house two larger and faster paper machines, was constructed. Because of the economic conditions--"the Great Depression"--of the time, only one machine was installed.

Bill Thompson,

The Powell River Mill Story

21

No. 7 Machine, described by the Powell River Digester as the final word in newsprint machine construction, was built by Dominion Engineering. It was a 1600 ton giant with suction couch, suction presses, a removable fourdrinier to facilitate and speed up wire changing, and 52 drier rolls. Powered by a Harland sectional direct current electric drive, the machine was designed to produce a sheet 214 inches wide at 1400 feet per minute and increase daily production by 150 tons (more than the combined production of Nos. 1 and 2 Machines. On December 30, 1930, No. 7 began producing salable newssprint,..............Bill Thompson,

The Powell River Mill Story

22

Construction, Number 7 Paper MachineCirca 1930

Powell River, British Columbia, Canada

Credits:

Credits:A18-40-1

23

The decision to install No. 8 Machine was announced late in 1946. No. 8 was the same width as No. 7. Built by Dominion Engineering Works Ltd. in Quebec, it was the first newsprint machine installed in Canada in 11 years. Most of the equipment required for it was made in Canada. No. 8 was set up beside No. 7 in the building constructed in 1930 for two identical machines.Bill Thompson

The Powell River Mill Story

24

Head box and Wet End, Number 8 Paper Machine2 September 1948

Powell River, British Columbia, Canada

Credits:

Credits:P00856

25

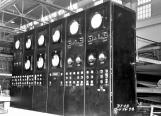

Electronic controls which were not available to No. 7 Machine in 1930 were included in No. 8 design. The stock inlet system, developed by Powell River Company engineers after extensive discussion with operating personnel, was of an entirely new design, operating with constant level and variable pressure.Bill Thompson,

The Powell River Mill Story

26

Wet end control panel, Number 8 Paper Machine26 October 1948

Powell River, British Columbia, Canada

Credits:

Credits:P00810

27

The drier section contained 52 main driers and 10 felt driers. The Pope reel, on which the finished sheet is wound as it comes from the calender, was designed to handle enough paper for two runs through the winder, saving time in moving reels from paper machine to winder.Bill Thompson,

The Powell River Mill Story