1

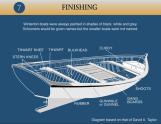

Internal structures2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

2

Before the finishing of the interior began a generous coat of hot tar might be applied to the inside of the bottom planks, underneath the floors, to create a more water resistant seal.Depending on the type, purpose or shape of the boat, the placement and size of the internal structures could vary slightly. For example, an extra thwart could be added for a larger boat, or there might or might not be an engine house.

4

The hull was now ready to have its seams caulked. Bulk oakum, hemp or other rope fibers impregnated with pine tar, was readily available from local merchants but had to be spun into long strands of the right diameter for the process.6

Oakum would usually be spun into strands of about one quarter of an inch for smaller boats.7

Caulking iron and wooden mallet2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

8

A caulking iron and wooden mallet were used to drive the oakum into each seam. This process prevented the boat from leaking.9

Curved boards are selected for gunwales2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

10

Installation of the gunwales, which included the top batten, covering boards (top board) and rubbers (outside board) was completed.The covering boards were fitted so they could be properly shaped around the boats topsides. These needed to be wide enough to cover the top batten thickness (usually three quarters of an inch), the width of the timbers (one and one quarter inches to two inches depending on the boat size), and the plank thickness.

11

Gunwales are fitted around the stem2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada

12

When the correct curve was achieved a notch was cut into the stem side of each of the covering boards so they would fit snugly around the stem.13

Covering boards2003

Winterton Boat Building and Community Museum, Newfoundland and Labrador, Canada