2

To understand the meaning and importance of the Strome Flour Mill, one should know something of the beginnings of milling and of how it was developed and on what it depends.Ever since wheat has been grown and flour milled, bread has been a necessity of human life. Bread is called "the staff of life." Some long ago discovery of the flour in wheat and barley led to the cultivation of these grains in every country where they can be grown, and grinding the grain into flour.

The first flour mill consisted of two stones, with the grain placed on the face of one stone, the nether millstone, and broken or crushed by the pounding of the other stone held by hand. Grinding, or turning one stone on the other, took the place of pounding or crushing in the growth of milling methods. These stones were usually round and flat and about two feet in diameter. The upper stone had a hole in the middle in which the grain was poured. The grinding surfaces were chiseled into grooves. The edges of the grooves did the grinding, while the meal worked its way along the grooves to the outer edge of the stone, and was poured out in the state of flour.

4

With such primitive implements for making flour, milling was at first a domestic industry. Every household ground its own grain for bread. The millstones were necessary household furnishings.Whether the upper millstone was lifted and let fall, as in pounding; or rolled, like a rolling pin; or pushed back and forth; or rotated about its centre on the nether millstone, and all of these methods were used in the development of milling; not much progress could be made in this industry so long as it was worked by hand. With the attachment of a long are or "sweep" to the upper revolving stone, a large grinding stone could be turned, either by man power or by animal power. During the Roman Empire, an ass or a number of slaves were attached to the sweep enabling the Roman Emperors to establish public mills to supply larger amounts of flour.

Eventually the Romans discovered that a rapid stream or waterfall furnished much more power than by hand or using animals. So, with the water-driven flour mill, a new era in milling was borne.

6

There wasn't any improvement in the process of milling from the time of the Roman Empire until the Eighteenth Century. Except for the windmill, no new motive power was introduced and no new inventions were brought out to replace the upper and the nether millstones used by the Romans.8

The invention of the steam engine in the Eighteenth Century and its application to milling marks the beginning of the modern flour mill. The steam engine meant the railroad, and the railroad made it possible to carry wheat to the mills, and to ship flour to distant markets. Steam power and electric power, railroads and steamships to carry flour from the wheat producing areas to people all over the world, are the foundation on which the great milling industry of the present day is built.10

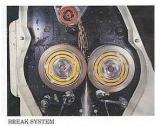

After the application of steam to milling, the next advance was the introduction of iron and steel rollers instead of stone grinders. The power of the steam engine, the improvement in gearing, coupling, belting and other forms of power transmissions that resulted from the mechanical inventiveness of the Nineteenth Century were the conditions that made the small metal rollers possible, and gradually dispensed with the heavy and clumsy stones.The first pair of rollers was not intended to break up the entire grain as the revolving stones had done, but rather to split the kernel, to tear it into pieces containing the valuable elements of the cereals, and to separate the bran. Each pair of rollers carries the process a stage further in separating the starchy materials from the bran, with the result that several different grades of flour are produced by every modern mill.

The whole process of flour-making is a triumph of mechanical skill, of scientific observation and of cleanliness.